Source: Link Testing Instruments Co., Ltd

By freezing the food quickly at an ultra-low temperature, it can be preserved from the time it is prepared to the time it is eaten. Frozen food slows down decomposition by turning residual moisture into ice, inhibiting the growth of most bacterial species. No extra preservatives are required because microorganisms do not grow when the temperature of the food is below −9.5 °C (15 °F), which is sufficient on its own in preventing food spoilage.

Today there are multiple options for packaging frozen foods: boxes, cartons, bags, pouches, Boil-in-Bags, lidded trays and pans, crystallized PET trays, and composite and plastic cans. No matter which kind of form of the frozen food package is, it must maintain its integrity throughout machine filling, sealing, freezing, storage, transportation, thawing and often cooking.

This article is going to discuss the low temperature resistance of frozen food package and how to guarantee the low temperature resistance of frozen food package. The low temperature resistance of package is evaluated by its impact resistance after a period of storage in low temperature environment. To be specific, the lower temperature resistance is proportional to its impact resistance. Therefore, if the package doesn’t have sufficient impact resistance, it may break during storage or transportation under low temperature. That’s why the manufacturers of frozen food should take measures to ensure the impact resistance of the frozen food package.

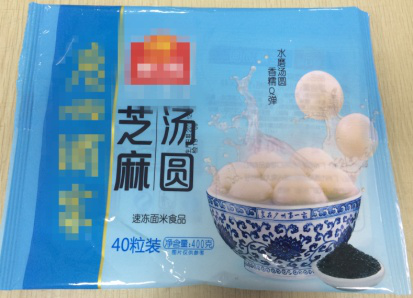

Figure 1. Frozen Food Package made of Composite Film

This article provides a simplified testing method for impact resistance of frozen food package. The specimens are plastic composite package supplied by one food company. The testing instrument is Link Testing’s LTJM-06 Pendulum Impact Tester.

The tests can be performed according to the following procedures.

With the test results obtained in the impact resistance tests, the users of plastic composite package for frozen food can determine whether the packaging materials can meet their requirements for low temperature resistance. Accordingly, the users can select most suitable materials to ensure the package quality and the product quality.

For more details about LTJM-06 Pendulum Impact Tester, please visit www.linktesting.org.

About Link Testing Instruments Co., Ltd:

Link Testing Instruments Co., Ltd is one leading supplier of packaging testing instruments, which is headquartered in Jinan, China.