Source: Link Testing Instruments Co.,ltd

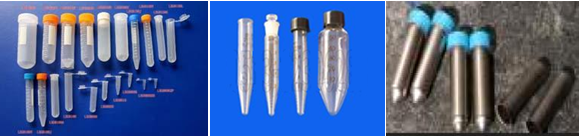

Centrifuge tubes are precision-made, high-strength tubes of glass or plastic made to fit exactly in rotor cavities. They may vary in capacity from 50 mL down to much smaller capacities used in microcentrifuges used extensively in molecular biology laboratories.

Most of those centrifuge tubes are sealed with caps. Those caps shall combine with the mouth of centrifuge tube tightly to form a completely enclosed space within the tube. Otherwise, the liquid contained inside the tube may leak and cause corrosion to the laboratory centrifuge, as a result, the service life of the laboratory centrifuge may be reduced. In addition, if the liquid inside the tube contains volatile constituents, the test results may be inaccurate due to the loss of volatile constituents. Therefore, it is necessary to examine the seal performance of the centrifuge tube before use.

This article provides a simplified test method of seal performance of centrifuge tube for your reference. The testing instrument used for the tests is Link Testing’s LTY-01 Leak Tester.

During the tests, the specimen is submerged in the water within the vacuum chamber, and then the vacuum chamber is evacuated to form differential pressure between the inside and outside of specimen. The leakage property could be obtained by observing the steady progression of bubbles from the specimen and how the specimen expands and restores to its original shape after vacuum release.

The most common materials used for plastic centrifuge tubes include PE, PC and PP. etc., among which the PP centrifuge tube is featured with best performance and most widely used in laboratory applications. The test specimens used in the tests mentioned in this article are PP centrifuge tubes.

The tests shall be performed according to the following procedures.

For more details about LTY-01 Leak Tester, please visit www.linktesting.org

About Link Testing Instruments Co., Ltd:

Link Testing Instruments Co., Ltd is one leading supplier of packaging testing instruments, which is headquartered in Jinan, China.