Source: Link Testing Instruments Co.,ltd

Packaging sealing performance refers to the characteristics of the package to prevent other substances from entering or the contents from escaping. If the packaging is poorly sealed, it is easy to cause air leakage, liquid leakage, or damage to the packaging during long-term circulation and storage after leaving the factory. The content has quality problems such as changes in taste and precipitation, and enterprises are therefore exposed to greater risks and economic losses. Therefore, the sealing problem of packaging has always been a major problem that plagues enterprises.

Beverages are generally packaged in paper, aluminum and plastic, plastic bottles or iron cans. This article uses PET bottle packaging as an example to introduce the overall sealing performance of plastic bottle packaging. If the sealing performance of PET bottles is poor, juice beverages are prone to leakage, while carbonated beverages It is easy to leak, and consumers cannot get the high-quality taste and other properties during use. Therefore, beverage manufacturers should strengthen the monitoring of the sealing performance of beverage packaging.

Test method and instrument

The Chinese testing standards for the sealing performance of beverage plastic packaging can refer to GB/T 15171-1994 "Test Methods for the Sealing Performance of Flexible Packages".

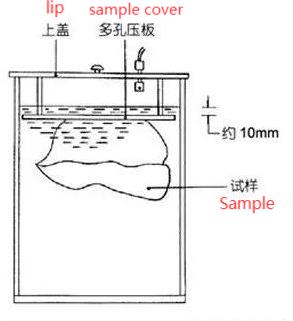

Test principle: By vacuuming the vacuum chamber of the equipment, the sample immersed in the water in the vacuum chamber generates a pressure difference between inside and outside, and checking whether the sample has leaks, so as to judge the sealing performance of the sample; or by checking the vacuum chamber Apply a vacuum to generate a pressure difference between the inside and outside of the sample. By observing the sample's shape recovery after the sample expands and releases the vacuum, the sealing performance of the sample is judged.

Test sample and test process

Test sample: beverage PET packaging bottle provided by a food factory.

Experimental procedure:

(1) Immerse the sample in the water in the vacuum chamber.

(2) Put on the sealing cover and set the vacuum pressure parameters and holding time to be reached.

(3) Turn on the vacuum generator, start vacuuming, and press the start button on the equipment to start the test.

(4) Observe whether continuous bubbles are generated at the mouth of the packaging bottle during the vacuuming process or during the pressure maintaining process.

Test results and analysis

The test results of the sealing performance of the 5 finished packages of the beverage in this test are: 2 of the finished packages showed no air leakage at -90 KPa; the other 3 finished packages showed air leakage at the mouth of the bottle when it did not reach -89 KPa. The leakage performance is poor.

Through the test of the sealability of beverage PET bottles, it is found that some of the packages have leaks, which can easily cause quality problems such as air leakage and liquid leakage in the finished package. Therefore, beverage companies should strengthen the sealing performance test of the finished package before leaving the factory. The LTY-01 leak tester is used to test the sealing performance of finished packaging. The test operation is simple, time-consuming and efficient, and it can accurately reflect the sealing performance of the beverage bottle.

For more details please visit www.linktesting.org