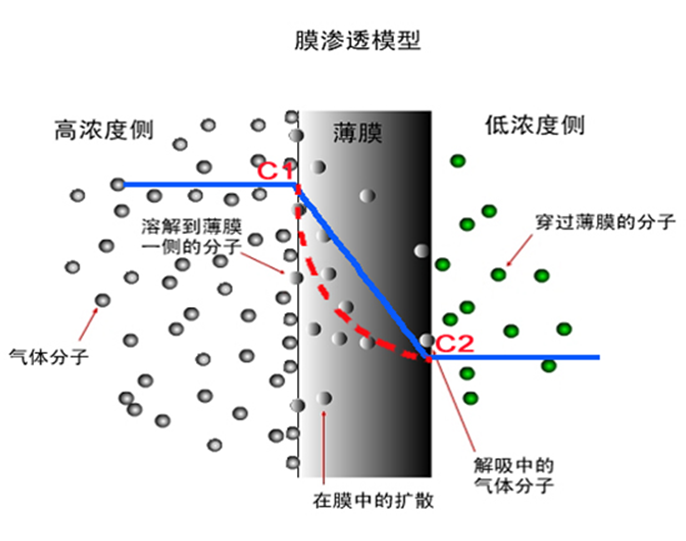

Mechanism of gas penetration through materials

Form the micro perspective, penetration of gases can be divided into five steps, as demonstrated in above picture:

Gas molecules or atoms contact and stay on the surface of film materials;

Dissolving;

gases at the high concentration side of the film reach solubility equilibrium;

Due to the concentration gradient, gases at the high concentration side start to diffuse to the other side, and concentration equilibrium will be reached after some time.

Resolving.

Pressure differential method

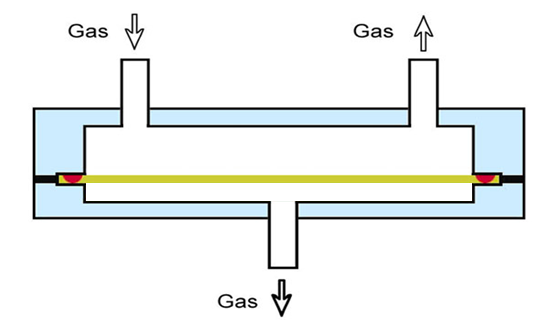

1.Vacuum method (standard)

Test principle: Specimen divides the cell into two independent chambers, and vacuumize the both chambers to certain degree. Introduce test gas into the upper chamber (or the high pressure side) till the absolute pressure reaches 0.1 Mpa, while the other chamber (or the low pressure chamber) remains in vacuum. Thus a o.1 Mpa pressure difference is formed. Test gas passes through the film into the low pressure chamber, causing the pressure change. Use high-precision pressure sensor to measure the pressure change in the low pressure chamber, and further determine the gas transmission rate (GTR).

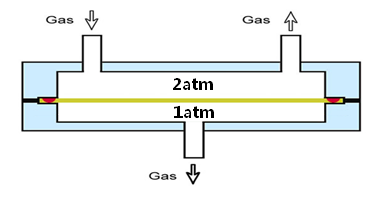

2. Positive pressure method (non-standard)

Test principle: Specimen divides the test cell into two test chambers. Inflate 0.2 Mpa absolute pressure into the upper chamber (high pressure chamber), and the other chamber (low pressure chamber) remains in ambient atmosphere pressure. O.1 Mpa pressure difference will be formed between the two sides of specimen. Test gas penetrates into the low pressure chamber from the other chamber. Use high precision sensor to measure the

pressure change in lower chamber and obtain the GTR.

Note:Relative pressure, also referred to as manometer pressure, is the pressure expressed on basis of barometric pressure. The other way to express pressure is absolute pressure which is expressed on basis of absolute vacuum.

Applications and Significance

Packages can not only facilitate the transportation and carrying of products, but also it can protect the packed contents, optimize the commodity appearance, extend the shelf life of products, and promote the sales. Plastics, as one of the four types of main packaging materials for modern commodities, has unparalleled advantages over glass, metal and paper materials, such as low raw material cost, low production cost, and low transportation cost.

Barrier property of plastic materials can preserve the authentic flavor of food and protect it from contamination by external factors. Transparent packaging can show people directly the packed contents, reducing the scratch and other damages caused by human touches. Barrier property of plastic packaging materials can preserve the authentic flavor and nutrition of food, and reduce the addition of preservatives. Pharmaceuticals are taken for human health, 3 / 33which requires that the packaging shall be able to maintain the safety, effectiveness, and reliability of pharmaceuticals under various conditions in long term.

Packages shall be made of proper plastic materials to form suitable barrier property, and such packages can be used to pack food and other products that may be easily oxidized or mildewed by oxygen and water content. Gas permeability test are performed to measure the permeation of particular gas through the materials with barrier property. Gas permeability test can help to determine whether packages for oxygen or other gases sensitive products could effectively keep such gases away from the packed contents, avoiding packed content deterioration.

Fresh food such as vegetables and fruit require that their packages shall have certain degree of gas or water vapor permeation, supporting their normal breathing. Breathing of fruit and vegetables includes both inlet of oxygen and outlet of carbon dioxide. Preservative films are required to measure both oxygen transmission rate and carbon dioxide transmission rate. Currently, preservative films are generally made of PE and PP.

In pharmaceuticals industry, glass infusion bottles are gradually replaced by plastic infusion bags and bottles. Some ingredients of the liquid medicine are oxygen-sensitive and may get oxidized when contacting with oxygen. The oxidization may change the medicine color, and disable the active constituents, such as vitamin C, metal ion, bromide, and alcohol components. Therefore, it is an effective way to preserve the liquid medicines and protect them oxidized through minimizing the oxygen content remaining in the packages and selecting infusing bags made of materials with good barrier property. In order to reduce the oxygen content, some infusing bags are filled with nitrogen, by which way the oxygen concentration would be decreased and the liquid medicines would be kept in a low oxygen or oxygen free environment. In order to preserve the nitrogen and maintain a high-nitrogen low-oxygen environment, infusing bags must have high barrier property to nitrogen, in other words, the nitrogen transmission rate of such materials must be low. Therefore, infusing bags shall perform both OTR and NTR tests.

For more details please visit www.linktesting.org