Source:Link Testing Instruments Co.,Ltd.

6. Preparations

Temperature: 73.4℉±3.6℉ (23 °C Relative humidity: 50±5%RH± 2 °C )

Forbid connecting the power supply with two live wires. The circuit layout shall conform to below diagram. Otherwise, the user is responsible for the delay of instrument training or any damage to the instrument(s).

At least 5 three-pin sockets are needed. And the power consumption for two of them is more than 1000W.

Dimensions of workbench: Width>80cm, height: 80~100cm is recommended, length >1.2m

At least one workbench as described above is required. It can stand more than 100Kg pressure per square meter.

| NO. | Item | Specifications | Qty. | Unit |

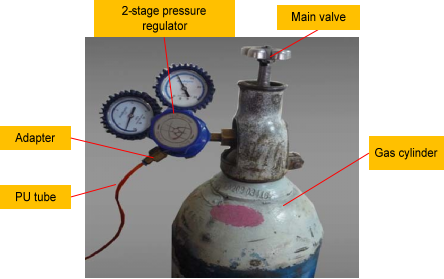

| 1 | Test gas cylinder (Fig. 1) (Test gas can be Air, N2, CO2 non-toxic or non-hazardous gas) | With purity of 99.95% or higher. Equipped with a2-stage pressure regulator (with adjustable output pressure between 5bar and 7bar). The outlet of regulator can be attached to Φ6 PU tube. It’s also acceptable if the outlet has M16X1.5 screw thread as an adapter for gas cylinder was supplied with the instrument. | 1 | Tank |

| 2 | Re-distilled water | only necessary for optional humidity generator | 20 | L |

| 3 | Potassium nitrate (KNO3) reagent | With purity 95% or higher (only necessary for optional humidity generator) | 1 | Bottle |

| 4 | Beaker and muddler | 250ml, for making saturated salt solution | 1 | Pce |

The gas source prepared by user must meet above requirements. If the purity is not qualified, test data will be greatly affected as well as the instrument.

The specifications of pressure regulator must meet above requirements.

If the outlet is not able to be attached toΦ6 PU tube or M16X1.5 adapter, the instrument cannot work properly.

If an unqualified pressure regulator is used, the instrument may be damaged.ay be damaged.

7 Disputes

There are some misunderstandings to test instruments of pressure differential method.

Low accuracy:

Some papers or people claim that instruments of pressure differential method are low in test accuracy, which cannot meet the test requirements of high barrier property materials. This is partial and merely a description to the fact in 1970s. Nowadays, vacuum technologies can ensure the 0.01 cc/m2*d (lower test limit) that is far enough for material testing. Besides, accuracy and precision of vacuum instruments will be continuously improved, which means that test capacity of pressure differential method instruments are not constrained by these factors. But the cost may increase significantly.

Some people believe that test efficiency of equal pressure method instruments is higher than that of pressure differential method. But it is not true. This improper view is related to the misunderstandings to test time and test efficiency of gas permeability test.

Test time shall be considered when evaluating the test efficiency of one test method. Different from other physical tests, both test specimen and test instrument need to be conditioned and adjusted in gas permeability test. Actually, the time taken by equal pressure method and differential pressure method from clamping the specimen to the end of testing is the same. We can divide the process into two stages. The first stage is pre-treatment. Test chambers of test instrument and gas pipe are inevitably to be contaminated by gas brought into them in specimen clamping. In other words, after specimens are clamped, there may be gas which is different from test gas in test chambers and gas pipes. The gas (not the test gas) may disturb the transmission of test gas, and further affects the test result.

Therefore, before testing, gas in test chambers and gas pipes must be purified.

What is relationship between gas purifying time and test time? As there is no definite definition to the test time of gas permeability, whether gas purifying time shall be counted into test time becomes random. And this is the source of the misunderstanding to test efficiency of gas permeability test. For example, evacuation time may be counted into test time by pressure differential method instruments, while purging time may not by equal pressure method instruments. Test time of gas permeability test shall include purifying time and permeation equilibrium establishing time. It is not proper to compare the test time of equal pressure method to the sum of evacuation time and test time of pressure differential method. Different test methods specify different system clearing means. For example, in pressure differential method, test chambers and pipes are evacuated, while in equal pressure method, test chambers and pipes are purged by large quantity of test gas. Therefore, clearing time is different. For pressure differential method, the system clearing time is the evacuation time before testing; while for equal pressure method, the clearing time is the system purging time with test gas (normally nitrogen).

Testing practices have proved that evacuation time is related with the volume of test chambers of pressure differential method instruments. Evacuation time would be shorter if volume of test chamber gets smaller. Evacuation time is specified in international reference standards. According to ASTM D 1434-82, test chambers have to be evacuated for an extra of at least 3h after required vacuum state is reached. Equal pressure method has definite requirements to the purging time. Purging time is affected by factors such as specimen material, specimen thickness, etc. Additionally, according to ASTM D 3985-05, purging time is divided into drying time and purging zero point time.

The second stage is transmission equilibrium time. It is the time taken by gas permeability test, and is mainly decided by the barrier property of the tested material. Transmission equilibrium time of equal pressure method and pressure differential method is almost the same when testing the same material. Generally, transmission equilibrium time for low barrier property materials is about 2h, 2-6h for medium barrier property materials, and higher than 6h for high barrier property materials.

Conclusion: Either from the test procedures or specific test instrument, test efficiency of pressure differential method has no obvious difference with that of equal pressure method. Therefore, it is partial and untrue for some papers believing that test efficiency of pressure differential method is low.

According to some people in the field, pressure difference formed across the specimen during testing may destroy the structure of fragile materials and generate flaws like cracks, pinholes, etc. besides, it may deform the specimen, affect its thickness, enlarge the transmission area, and further affecting the test result. Such concerns become more serious when equal pressure method is applied in USA. Can pressure difference across the specimen really affect the gas permeability of materials? Is test data obtained in this case accurate and reliable? These are never proved with detailed data.

Link Testing center and Hunan University of Technology (HUT) undertakes a subject study. The test is made in standard laboratory conditions, i.e., ambient temperature 23℃, humidity 50%RH, temperature of test chamber 40℃, and humidity of test gas 0%RH. The test lasts for about 3 months, during which more than 80 types materials are tested. Tested materials include polymers such as PC (125μm), PC (175μm), PET (12μm), PET (23μm), PET (25μm), PET (70μm), PA (35μm), PE (40μm), CPP (40μm), and OPP (38μm), and composite materials such as PE/EVOH/PE (55μm) and PA/PE (80μm). Barrier property of materials varies hugely, with gas permeation ranging from 1.49cm3/m2•24h•0.1MPa to 7030cm3/m2•24h•0.1MPa. Each specimen is going to be measured at pressure difference of 30 kPa, 50 kPa, 70 kPa, 90 kPa, 110 kPa, 130 kPa, and 150 kPa in sequence.

We are not going to list the detailed test results here. Details can be referred to the documents listed in Link Testing website. From the information we can get that pressure difference has no affect to gas permeability of materials.

Based on the fact of pressure difference, differential pressure method adopts some effective measures to make sure that specimens are not going to be deformed under pressure. Actually, lower chamber is very small, and specimen is fixed by quick quantitative filter paper and surface of the chamber. Within the range of pressure difference specified by the differential pressure method, the theoretical value and test result are in coincidence, which proves that pressure difference will not affect the barrier property of materials. In other words, permeation R and permeability coefficient P are not to change with the variation of pressure difference.

This conclusion made a hit in the annual conference organized by World Packing organization in UK. Coincidentally, one Danish institute published their research that permeability has no difference under pressure difference of 1 kg and 10 kg. Both conclusions complement each other, and became the highlight of the conference.

For more details please visit our website www.linktesting.org