Source: Link Testing Instruments Co.,Ltd.

The compatibility of food packaging and food contents means that within the space and time range of product circulation, the packaging can meet the requirements of not allowing the contents to deteriorate, not allowing toxic and harmful substances to migrate into the contents, and the packaging appearance is exquisite, in line with the product's market positioning, and can accurately convey product information. This requires that the packaging can maintain good barrier properties, physical and mechanical properties, and hygienic properties before and after it is used to package the contents, and the printing design is exquisite. Composite film materials are an important part of food packaging. This type of material mainly uses adhesives to combine different types of single-layer films together to give full play to the performance advantages of each single-layer film. For this type of material, peel strength is an extremely important physical and mechanical property that characterizes the composite strength of each single-layer film. The level of this indicator directly affects the overall oxygen permeability, water vapor permeability, and physical and mechanical properties such as impact resistance and puncture resistance of the material.

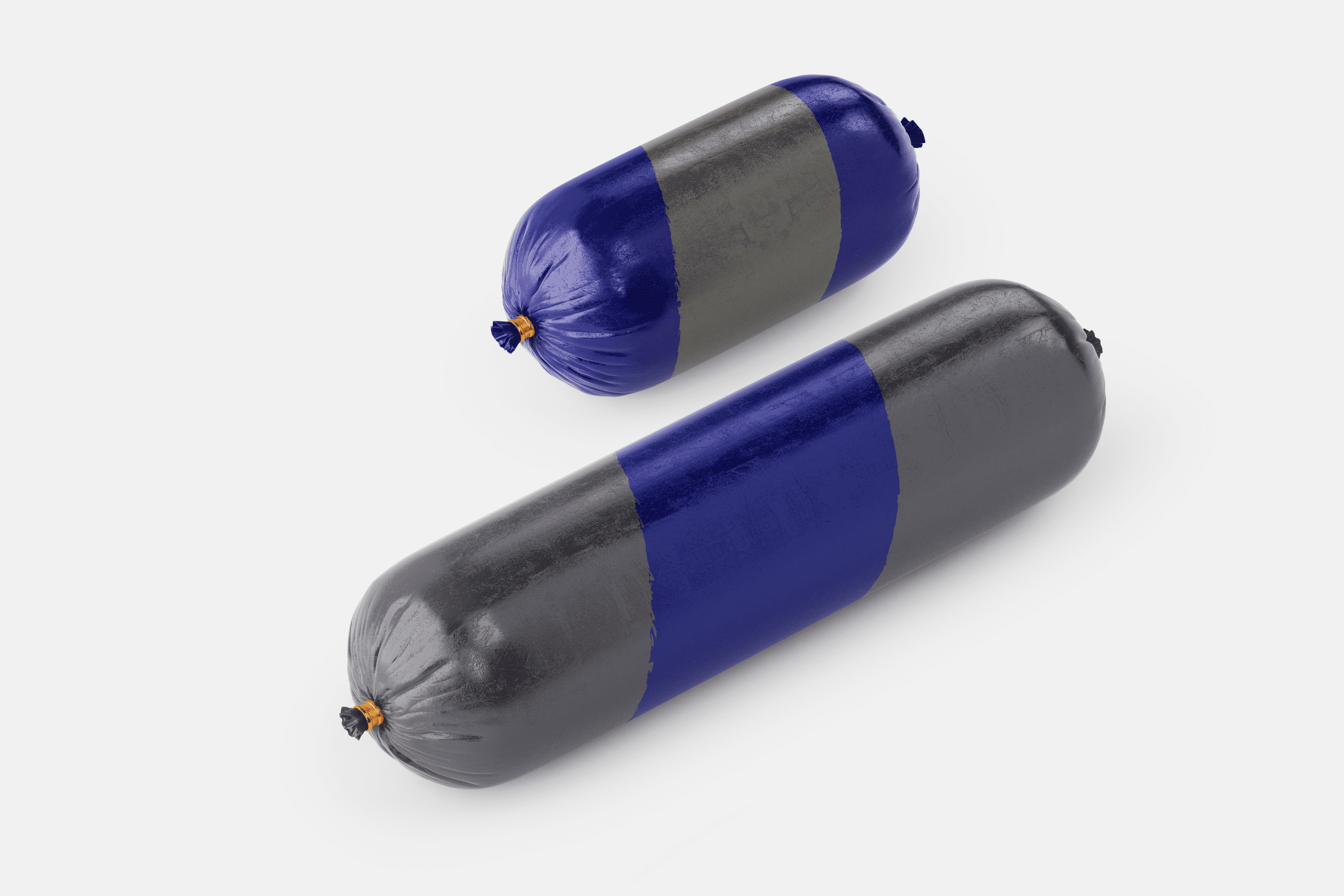

Ham is a processed aquatic product that contains a certain amount of fat and has been sterilized. Commonly used packaging includes plastic composite film, aluminum-plastic composite film, etc. If the adhesive used in the packaging composite has poor oil resistance or high temperature resistance, the composite fastness will be reduced after being used to package flavored fish, and even stratification will occur. This phenomenon will not only reduce the material's oxygen barrier performance, impact resistance and puncture resistance, causing ham to easily oxidize, deteriorate, mold, break bags and other quality problems, but also affect the product appearance and brand image. Therefore, it is extremely necessary to analyze the composite fastness of the packaging.

Test method and test instrument

This test is based on the relevant provisions of the high temperature medium resistance in the product standard GB/T 21302-2007 "General Rules for Composite Films and Bags for Packaging". The test equipment is the XLW-500N intelligent electronic tensile testing machine developed and produced by Link Testing. XLW-500N is an electronic tensile testing machine professionally used to test the tensile properties and other mechanical properties of various flexible packaging materials. It is suitable for the tensile, peeling, deformation, tearing, heat sealing, adhesion, puncture and other performance tests of plastic films, adhesives, adhesive tapes, self-adhesive stickers, medical patches, protective films, combination covers, backboard materials, non-woven fabrics, rubber, paper fibers and other products.

Test principle: The compatibility of the composite fastness of the composite film material with the food content is analyzed by comparing the change in the peeling strength of the material before and after contact with the content simulant. The peeling strength is the force required to peel off a composite film material of a certain width. During the test, the two layers of the sample peeled off in advance are clamped in the upper and lower fixtures of the intelligent electronic tensile testing machine. The upper fixture is a dynamic fixture equipped with a force sensor and a displacement sensor. The upper fixture drives the sample to peel when it moves upward at a set speed. The force sensor records the force change during the peeling process in real time, thereby obtaining the peeling strength of the sample.

Test sample and test process: In this test, the aluminum-plastic composite film purchased by a certain enterprise for ham packaging was used as the test sample.

Test process:

(1) Take 5 packaging bag samples, fill them with a certain amount of olive oil, and seal them with air.

(2) Place the package containing olive oil in a cooking pot, and after high-temperature treatment at 121℃ for 40 min, cool it, and take out the sample. Pour out the vegetable oil and wipe the surface of the sample with filter paper.

(3) Cut 5 samples with a width of 15.0 mm and a length of about 15 cm from the longitudinal direction of the untreated and treated packaging bag samples.

(4) Manually peel off the heat seal layer and the secondary inner layer from one end of each sample, and the peeling length is about 5 cm.

(5) Turn on the intelligent electronic tensile testing machine, set parameters such as sample width, test speed, sample name, etc., take one of the pre-peeled samples, and clamp the two ends of the peeled part in the upper and lower clamps respectively, so that the longitudinal axis of the peeled part coincides with the center line of the upper and lower clamps. Click the test option, the test starts, the upper clamp moves upward to peel the sample, and the equipment automatically records and displays the peeling force value during the test. After the test is completed, the equipment displays the peeling force of the tested sample. Repeat the sample loading test until all 10 samples are tested.

Test results and analysis: The test property is the longitudinal peel strength between the heat seal layer and the secondary inner layer of the sample. The average peel strength of the 5 untreated samples is 6.314 N/15mm, and the average peel strength of the 5 treated samples is 4.767 N/15mm, which means the peel strength has decreased by about 25%.

This paper analyzes the compatibility of ham and aluminum-plastic composite film samples in terms of composite fastness. After the sample packaging was filled with olive oil, the peel strength decreased by 25% after high temperature treatment, which meets the provisions of GB/T 21302 that the peel strength reduction rate is ≤30%. The compatibility of this sample with ham is good. From the perspective of the entire test process, the test is simple, the equipment is easy to operate, and the degree of intelligence is high.

For more details please visit www.linktesting.org