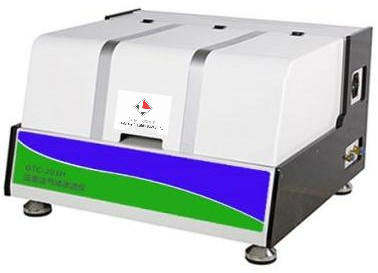

Source:Link Testing Instruments Co.,Ltd.

The instrument adopts the differential pressure test principle, and the pre-processed sample is placed between the upper and lower test chambers and clamped. First, the low-pressure chamber (lower chamber) is vacuumed, and then the entire system is evacuated; when the specified vacuum degree is reached, the lower test chamber is closed, and a certain pressure of test gas is filled into the high-pressure chamber (upper chamber), and a constant pressure difference (adjustable) is formed on both sides of the sample; in this way, the gas will penetrate from the high-pressure side to the low-pressure side under the action of the pressure gradient, and the various barrier parameters of the tested sample can be obtained by monitoring and processing the internal pressure of the low-pressure side.

2. Scope of Application

The instrument is designed and manufactured in accordance with the relevant provisions of the national standard technical requirements of GB 1038, and can also meet the test requirements of multiple international standards such as ASTM D1434, ISO 2556, ISO 15105-1, and JIS K7126-A. It is suitable for the determination of gas permeability, solubility coefficient, diffusion coefficient and permeability coefficient of various films, composite films and sheets at various temperatures, and can provide reliable and scientific data reference for scientific research and new product development.

3. Maintenance content and process

1.Clean the machine body. Regularly clean the instrument in a comprehensive and systematic manner. Turn off the main power of the equipment and wipe the dust and stains on the machine body, especially the concave corners, with a dry cloth.

2.Check the liquid level of the vacuum oil. Before each test, check that the oil level in the vacuum pump should be within the specified range (between the two lines).

3.Replace the vacuum oil. Regularly check the changes in the vacuum oil quality in the vacuum pump. If the oil quality is obviously contaminated or the vacuum pump noise is too loud during operation, the specified model of vacuum oil should be replaced in time.

4.Check the liquid level of distilled water. Before each test, check that the liquid level in the temperature control device should be within the specified range (the liquid medium level cannot be lower than 40mm of the workbench and should cover the heating tube).

5.Replace the distilled water and regularly check the changes in the water quality in the temperature control device. If the water quality is obviously polluted, the distilled water should be replaced in time.

6.Clean the heat sink of the temperature control device and regularly clean the dust on the surface of the heat sink on the front side of the temperature control device to avoid too much dust affecting heat dissipation.

4. Maintenance period

5. Precautions

For more details please visit www.linktesting.org