Source: Link Testing Instruments Co.,Ltd.

I. Core Content of the Standard

This standard specifies the test methods for determining the dynamic friction coefficient (μD) and static friction coefficient (μS) of light-duty conveyor belts.

Static friction coefficient (μS): The ratio of the maximum tensile force to the compressive force during the process from a stationary state to the start of relative motion of the sample.

Dynamic friction coefficient (μD): The ratio of the average tensile force to the compressive force during the uniform motion of the sample.

Dynamic friction coefficient (μD) ≤ 1.0

Static friction coefficient (μS) ≤ 1.5

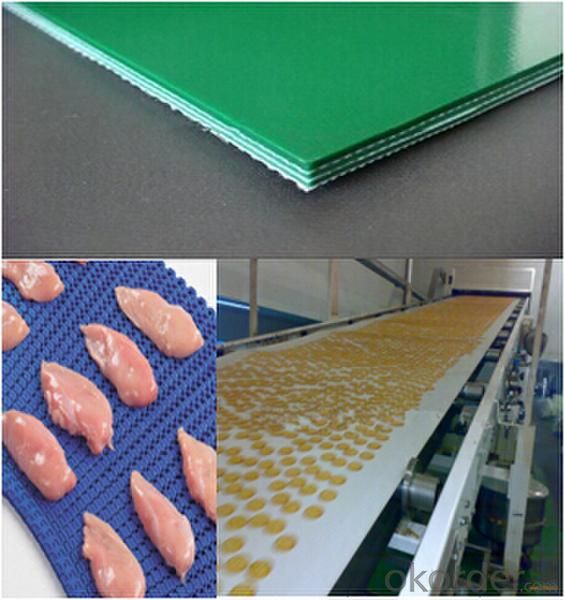

This standard applies to light-duty conveyor belts and not to special conveyor belts with high friction coefficients.

II. Detailed Test Method

Metal Test Plate: 76mm × 131.5mm × 0.8mm, surface roughness Ra: 0.9-1.3μm

Test Plate Usage Limit: ≤50 cycles or 1-day cycle

Force Measurement System: Meets ISO 7500-1 Level 3 accuracy or higher

Normal Force Loading: 71mm high steel weight (7.85g/cm³)

Test Speed

Dynamic Friction Coefficient: 1000±20 mm/min

Static Friction Coefficient: 100±10 mm/min

Force Calculation

Dynamic Friction Coefficient: FD/FN (Last 200mm Stroke)

Static Friction Coefficient: FS/FN (Starting Point of Motion)

Test Distance

Dynamic Friction Coefficient: 300mm

Static Friction Coefficient: 300mm

Dimensions: 600mm × 100mm (Full Thickness)

Quantity: 3 each in the longitudinal and transverse directions

Conditioning: ≥24h under ISO 18573 Environmental B conditions

Special Requirements: Testing can only be performed 5 days after production

III. Test Procedure

Sample preparation should be done at least 5 days after production before testing to ensure material performance stability.

IV. Advantages of Link Testing Equipment

Precise Standard Compatibility:** The LTMXS-06 friction coefficient tester uses a high-precision sensor (accuracy better than 0.5 grade), meeting the requirements of ISO 7500-1 force measurement systems. Test results are highly consistent with GB/T 33205-2016.

Ease of Operation:** An industrial-grade color high-definition touchscreen with a menu-driven interface supports one-button switching between static and dynamic friction coefficients. Data is displayed and stored in real time, reducing human error.

Multi-Scenario Compatibility:** In addition to conveyor belts, it can test materials such as films, rubber, and paper, covering the needs of multiple industries including food, pharmaceuticals, and packaging.

For more details please visit www.linktesting.org