Source: Link Testing Instruments Co.,Ltd.

1. Film heat shrink tester

The heat shrink of the film has been applied as early as 1936. At first, rubber film was mainly used for shrink wrapping perishable food. Heat shrinkable film packaging is a widely used form of packaging, with the characteristics of compact packaging, transparent and beautiful, and strong adaptability. In addition, shrink wrap is used to create shrink labels (such as labels for Coke bottles) and shrink caps (such as red sprinkle packaging), allowing containers that are not easily printed or intricately shaped to be labeled.

The heat shrinkable film is a polymer material. The shrinkage principle is that when the temperature is stretched at high temperature, the molecular segments are oriented in the stretching direction, and the disordered and curled molecular segments are arranged in an orderly manner. When the temperature drops rapidly, the molecular segment orientation structure and The internal stress is "frozen", and when the polymer is heated to the stretching temperature again, the molecular segments are de-oriented and return to the disordered coiled state, which manifests as thermal shrinkage macroscopically. Shrinkage force and shrinkage rate are the main indicators to determine whether the shrinkage performance is good or bad.

Test principle

Connect the sample to be tested to the force sensor and displacement sensor, quickly heat up to the shrinkage temperature, and then cool down. The system automatically records the shrinkage force, temperature, shrinkage rate and other parameters in real time, and analyzes the measurement results.

2. Product application

The heat shrinkable film made of PET, PVC and PP uses the heating principle to shrink the sleeve label for packaging. Whether the label can maintain a good fit during the shrinking process needs to be monitored whether its shrinkage rate, shrinkage force and other indicators are appropriate. During the heat shrinking process of the sleeve label, if the shrinkage rate is too large, or the shrinkage force (including the heat shrinkage force and the cold shrinkage force) is too high, it will easily lead to an increase in the consumption of the label, and the excessive shrinkage of the label will cause the printing pattern to be deformed. In severe cases, the plastic bottle body will be deformed. If the shrinkage rate of the label is small and the shrinkage force is too low, the label will not fit the bottle body easily. Therefore, timely monitoring of the shrinkage performance of the heat shrinkable label film has a key guiding significance for ensuring the beauty of the beverage bottle body and reducing the packaging cost.

Heat shrinkable film is widely used in: food, medicine, disinfection tableware, stationery, craft gifts, printed matter, hardware and plastic products, telephones, electronic appliances, etc. In terms of combined (cluster) packaging, it can not only meet the functions of moisture-proof and dust-proof, anti-touch and stealing, transparent display, etc., but also increase the attractiveness of product appearance, and can also be used to replace various types of cartons, but it saves packaging costs and In line with packaging trends.

3. Feature Interpretation

3.1 Microcomputer control, LCD display, PVC operation panel, menu interface.

Microcomputer control effectively avoids the influence of human factors on the test, and at the same time, it is easy to operate and has good human-computer interaction. The menu-type interface is convenient for selection and setting, the large LCD screen displays a large amount of information, and the parameter setting is clear at a glance, which is convenient for operation.

3.2 Digital P.I.D temperature control.

PID temperature control can not only quickly reach the set temperature, but also effectively avoid temperature fluctuations.

3.3 Heating of liquid medium provides a stable test environment.

3.4 The system will automatically time the time, and a buzzer will sound when the test is over.

The time adopts microcomputer integrated control, the control is more accurate, the interference of human factors is effectively avoided, and the accuracy of the test data is guaranteed.

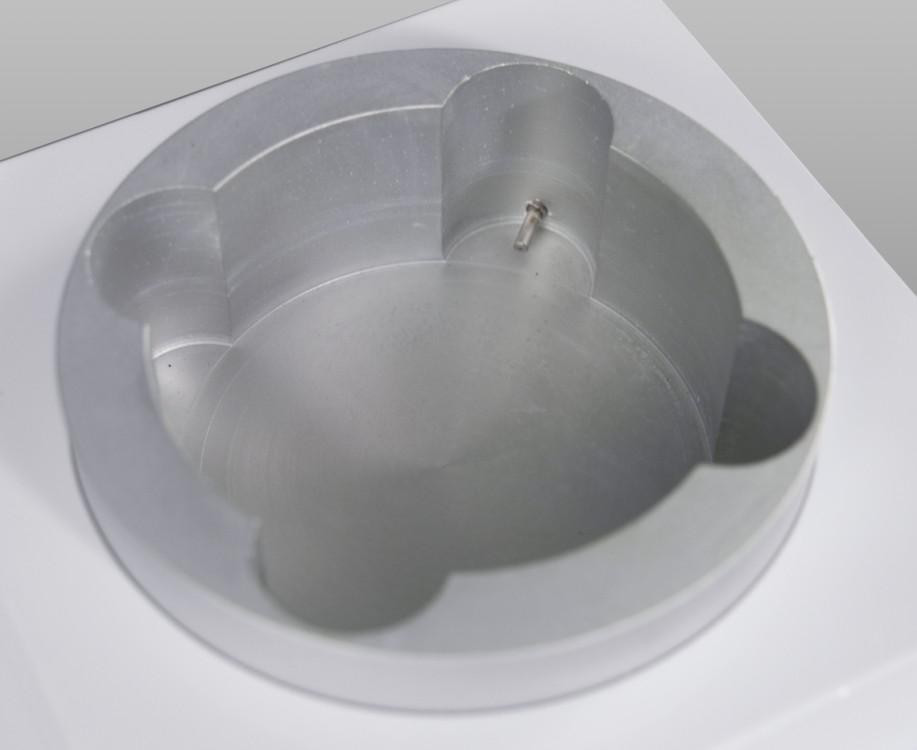

3.5 Equipped with a standard sample clamping film grid to ensure the smooth progress of the test.

Here are the laboratory requirements and precautions for LTRSY-03 Film Free Shrink Tester for your information. Please read it carefully before you start to use the instrument to ensure proper installation and operation in the future.

Relative humidity: 50±5%RH

1.2 The power supply should be single-phase AC 220V, 50Hz/60Hz and be connected to the earth reliably. (Note: If you are located in America, Japan or Taiwan, the instrument is already designed for AC 110V, 60Hz. The details of power supply are subject to the statements in Operator’s Manual.) Forbid hanging earth wire in the air. Neutral wire and Earth wire cannot be connected. The instant fluctuation of voltage between live wire and neutral wire should be less than 5V. If it’s bigger, the user must purchase a stabilized voltage supply with power consumption 1500W to meet test requirement.

Forbid connecting the power supply with two live wires. The circuit layout shall conform to below diagram. Otherwise, the user is responsible for the delay of instrument training or any damage to the instrument(s).

At least one three-pin socket is needed.

Power consumption: 1500W

At least one workbench as described above is required. It can stand more than 100Kg pressure per square meter.

| Item | Specifications | Quantity | Unit | |

| 1 | Tools for cutting samples | knife, straight ruler and rubber pad (See Fig. 1) | 1 for each | Pce |

| 2 | Methyl silicone oil or dimethyl silicon oil | >1kg |