Source: Link Testing Instruments Co.,Ltd.

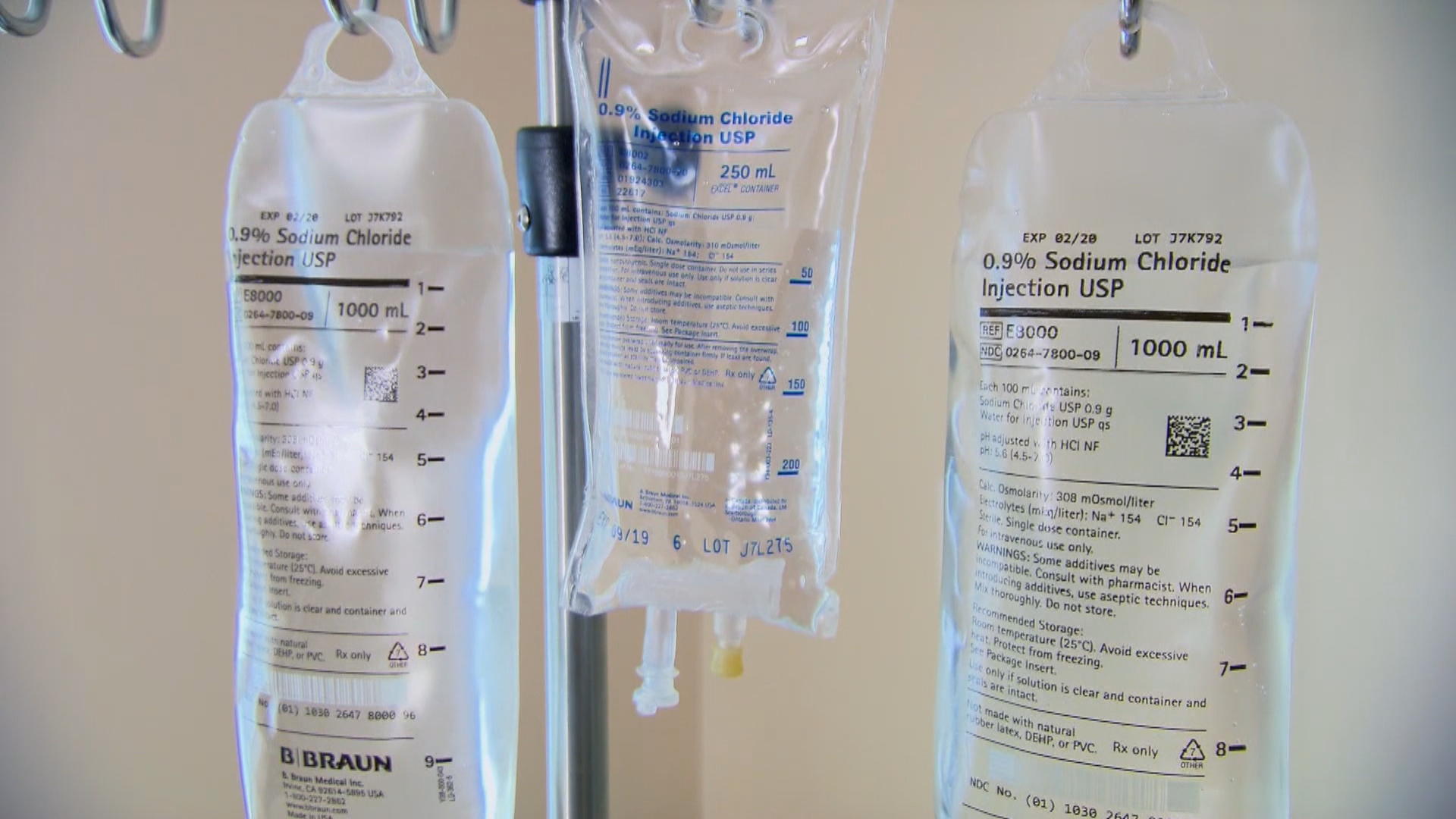

With the gradual increase in the types of flexible packaging and the continuous improvement of performance, traditional glass infusion bottles are being replaced by plastic infusion bags. Common soft plastic infusion bags are mostly made of polypropylene, polyethylene, polyamide and various elastic materials through co-extrusion process. Compared with traditional glass bottles, soft plastic infusion bags are environmentally friendly, hygienic, and not fragile. It has the advantages of convenient use and transportation, but in order to ensure that the liquid medicine does not leak during transportation and storage, and the quality is good, the heat seal strength of the infusion bag seal is a performance that has to be considered during use.

The heat seal is a barrier that separates the liquid medicine in the infusion bag from the external environment. If the heat seal strength is poor, the liquid medicine will easily leak, and the gas in the environment will easily penetrate into the infusion bag, causing the liquid medicine components to oxidize and fail, and even Harmful substances are produced. In addition, if the bag is squeezed or dropped by external force during transportation or storage, the bag may be broken at the poor heat seal. During the filling process of the liquid medicine, the liquid droplets are likely to contaminate the heat seal, which will affect the heat seal strength of the seal edge. Therefore, it is necessary to strengthen the measuring of the heat seal strength of the medicinal infusion bag.

Test Methods and Test Instruments

The test process is based on the pharmaceutical packaging material standard YBB00122003-2015 "Heat Seal Strength Test Method". This standard is applicable to the determination of the heat seal strength of plastic heat seals on plastic or other material and the heat seal strength of plastic composite bags.

The test uses the LTS-05 Automatic Tensile Tester to test the heat seal strength of the samples. This instrument is independently developed and produced by Link Testing Instruments Co.,Ltd. LTS-05 is a professional instrument for testing the mechanical properties of various medical packaging materials; its ultra-high precision (level 1) ensures the accuracy of the test; 16 independent test procedures, various specifications of force sensors, And tensile and compression two-way test mode, which can meet various test needs of users.

Principle of heat seal strength test: heat seal strength refers to the force value required to pull apart and destroy the heat seal edge. The heat-sealed edge is pulled apart and destroyed, and the upper clamp is equipped with a force sensor, which can monitor the change of the force value during the process of the heat-sealed edge being destroyed in real time, and display the tested force value on the force value curve, so as to obtain the Heat seal strength.

Test sample and test process

Test sample: The test takes a certain brand of infusion bag as the test sample to test its heat seal strength.

Experimental procedure:

(1) At the four heat-sealed edges of the sample, cut a total of 10 samples with a width of 15 mm and an unfolded length of at least 100 mm along the direction perpendicular to the heat-sealed edge.

(2) Set the parameter information such as sample name, test speed 300 mm/min, and sample width 15 mm.

(3) Take one of the samples, open it with the heat-sealed edge as the center, clamp both ends of the sample in the upper and lower clamps of the instrument, make the axis of the sample coincide with the center line of the upper and lower fixtures, and heat-seal the edge Try to be equal to the distance between the two fixtures.

(4) Click the start option to start the test. The upper fixture moves upward according to the set test speed, and drives to destroy the heat-sealed edge, and displays the change of force value in real time.

(5) After the test, the instrument displays the heat seal strength of the tested sample.

(6) Repeat (3) ~ (5) until all 10 samples are tested.

Test Results and Analysis

The test results of the 10 samples are 35.625 N/15mm, 33.649 N/15mm, 34.056 N/15mm, 36.790 N/15mm, 32.483 N/15mm, 36.020 N/15mm, 34.631 N/15mm, 33.549 N/15mm, 34.156 N/15mm, 36.048 N/15mm, the heat seal strength of the tested medicinal infusion bag sample is 34.701 N/15mm, which is the average value of the test results of 10 samples. Good heat-sealing strength is one of the necessary conditions to keep the packaging of medicinal infusion bags intact and to ensure the efficacy of medicines.

Strengthening the monitoring of heat-sealing strength of infusion bags has far-reaching significance. LTS-05 automatic tensile tester can accurately test the heat seal strength of the infusion bag, and the instrument is easy to operate, and the test data has good repeatability, which can well reflect the heat seal condition of the heat seal edge of the infusion bag. In addition to testing the heat seal strength, this instrument can also be used to test the tensile properties, tear properties, composite fastness of medical packaging bags, the adhesiveness of medical tapes, the puncture resistance of rubber stoppers, and the use of infusion bags. Applicability, the use performance of injections, etc., is a very cost-effective testing instrument.

For more details please visit www.linktesting.org