Source: Link Testing Instruments Co.,Ltd.

The burst pressure test is the overall impact and extrusion resistance of the packaging bag. Regular and timely monitoring of the burst pressure of the packaging bag can effectively prevent the packaging bag from being impacted, dropped, or damaged due to insufficient toughness of the packaging material or poor sealing. Damage during extrusion is of great significance to reducing the damage rate of finished packaging in the circulation process.

Pet food is food specially provided for pets and small animals. It is a high-end animal food between human food and traditional livestock and poultry feed. It is generally packaged in bags or tin cans. For non-vacuum packaged pet food that contains a certain amount of gas, if the finished product is packaged in transportation, sales and other circulation links, the packaging bags squeeze each other, fall or are hit by external forces, etc., which will cause the pet food inside the package to Or the gas will have a large impact on the packaging bag body and seal. If the flexibility of the packaging material is poor or the seal is poorly sealed, the bag will easily break. By testing the bursting pressure of packaging bags, the weak parts of the packaging and the overall stress level can be verified, providing reference for companies to control the quality of packaging materials, improve heat sealing processes, and adjust packaging processes.

Test methods and instruments

At present, domestic method standards for burst pressure testing of flexible plastic packaging have not yet been released. The testing process mainly refers to the American standard ASTM F1140/F1140M-2013 "Test Method for Resistance to Internal Pressure Damage of Unconstrained Packages."

This test uses the LTMFY-06S leakage and sealing strength tester developed and produced by Link Testing to detect the burst pressure of pet food aluminum-plastic composite film packaging bag samples.

Test principle: The equipment is designed using the positive pressure method test principle, that is, the gas pressure inside the sample is greater than the outside. By filling a certain amount of gas into the sample package and monitoring the pressure changes in the package in real time until the package ruptures, the pressure value tested at this time is the burst pressure of the package, or filling the sample with gas to specified pressure, and then place the sample in water or use other methods to check whether the sample is leaking. In either case, under the impact of the gas inside the package, the weakest link in the package will break or leak first. Therefore, based on the location of the breakage or leakage of the package, the weakest part of the package can also be inferred.

Test samples and test process

Test sample: Aluminum-plastic composite film bag for pet food packaging of a certain brand.

Experimental procedure:

Test results and analysis

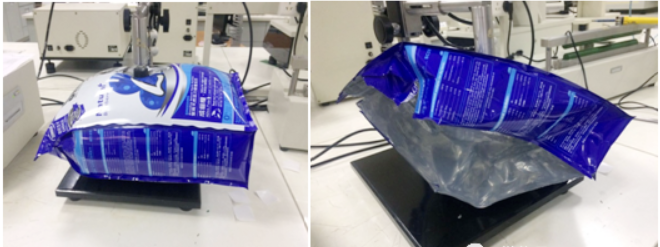

A total of 3 bags of samples were tested in this experiment. The burst pressures of each sample were 40.5 KPa, 41.8 KPa, and 40.7 KPa respectively, and they all broke at the side sealing edge of the sample.

The leakage and sealing strength tester is professionally suitable for quantifying the sealing strength, heat sealing quality, bursting pressure of the whole bag, and sealing leakage performance of flexible packages, sterile packages, etc. formed by various heat sealing and bonding processes. Determination; analysis of the compressive strength, bursting strength and other indicators of the materials used in flexible packaging bags; quantitative determination of the sealing performance of various plastic anti-theft bottle caps, bottle cap connection tripping strength, and material stress strength; bottle sealing, resistance Evaluation and analysis of pressure resistance, burst resistance, etc.; quantitative measurement of various hose overall sealing performance, pressure resistance strength, cap body connection strength, tripping strength, heat sealing edge sealing strength, tie strength and other indicators.

For more detail please visit www.linktesting.org